does anyone knowing anyone mod'ding lt1 fuel rails like this?

#1

Race Director

Thread Starter

0409Htp Snow 09 Z Photo 9

http://www.gmhightechperformance.com.../photo_09.html

I want to convert my fuel rails to support eventual big forced induction HP. Im already running 2 fuel pumps.

Does anyone know anyone who is modifying lt1 fuel rails like this?

I can weld steel, but Im really a little nervous about welding aluminum fuel rails. Id be afraid id put too much heat history into them or end up w/ a pinhole leak somewhere.

Thanks!

http://www.gmhightechperformance.com.../photo_09.html

I want to convert my fuel rails to support eventual big forced induction HP. Im already running 2 fuel pumps.

Does anyone know anyone who is modifying lt1 fuel rails like this?

I can weld steel, but Im really a little nervous about welding aluminum fuel rails. Id be afraid id put too much heat history into them or end up w/ a pinhole leak somewhere.

Thanks!

#3

Melting Slicks

Member Since: Jun 1999

Location: Bowling Green KY

Posts: 2,948

Likes: 0

Received 21 Likes

on

16 Posts

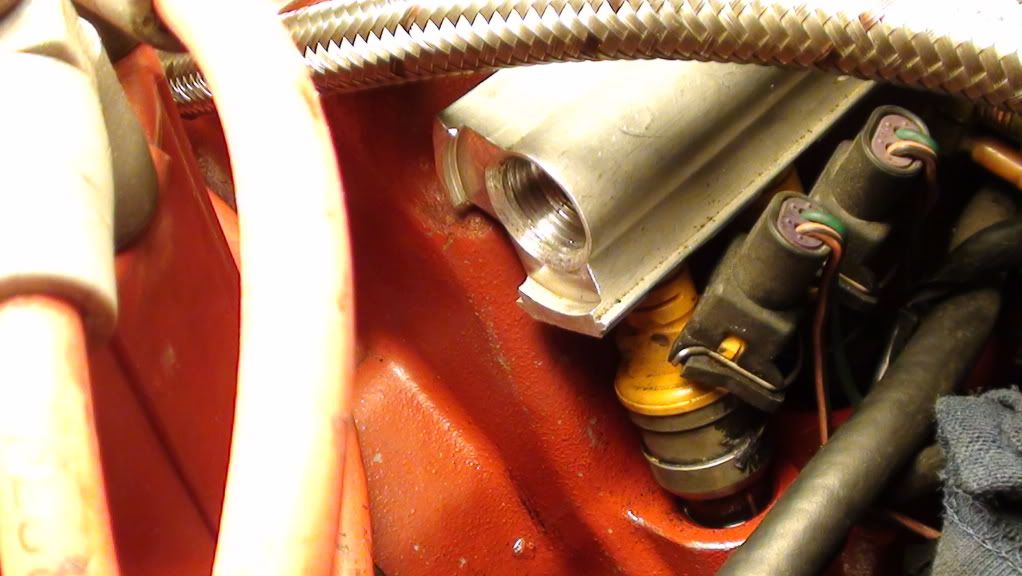

When I did my solid rear my chassis guy modified mine:

I considered going the route shown in your link, but frankly there are some pretty high horsepower cars running non-modified rails, and it's hard to make the true dual line setup like you show "clean" looking - mine looks factory more or less (actually cleaner).

I don't know the first thing about welding, be it steel or aluminum, but if your weren't comfortable doing it I would think someone could do it pretty cheap for you.

I considered going the route shown in your link, but frankly there are some pretty high horsepower cars running non-modified rails, and it's hard to make the true dual line setup like you show "clean" looking - mine looks factory more or less (actually cleaner).

I don't know the first thing about welding, be it steel or aluminum, but if your weren't comfortable doing it I would think someone could do it pretty cheap for you.

#4

Race Director

0409Htp Snow 09 Z Photo 9

http://www.gmhightechperformance.com.../photo_09.html

I want to convert my fuel rails to support eventual big forced induction HP. Im already running 2 fuel pumps.

Does anyone know anyone who is modifying lt1 fuel rails like this?

I can weld steel, but Im really a little nervous about welding aluminum fuel rails. Id be afraid id put too much heat history into them or end up w/ a pinhole leak somewhere.

Thanks!

http://www.gmhightechperformance.com.../photo_09.html

I want to convert my fuel rails to support eventual big forced induction HP. Im already running 2 fuel pumps.

Does anyone know anyone who is modifying lt1 fuel rails like this?

I can weld steel, but Im really a little nervous about welding aluminum fuel rails. Id be afraid id put too much heat history into them or end up w/ a pinhole leak somewhere.

Thanks!

Your are net welding are you, just tapping a hole on the end of the rail?

#5

Le Mans Master

Member Since: Oct 2004

Location: Everett WA

Posts: 7,690

Received 477 Likes

on

353 Posts

C4 of Year Finalist (appearance mods) 2019

0409Htp Snow 09 Z Photo 9

http://www.gmhightechperformance.com.../photo_09.html

I can weld steel, but Im really a little nervous about welding aluminum fuel rails. Id be afraid id put too much heat history into them or end up w/ a pinhole leak somewhere.

Thanks!

http://www.gmhightechperformance.com.../photo_09.html

I can weld steel, but Im really a little nervous about welding aluminum fuel rails. Id be afraid id put too much heat history into them or end up w/ a pinhole leak somewhere.

Thanks!

We build these boats as turn-key custom units manufactured completely out of aluminum.

http://www.kvichak.com/

#8

P.S. if you strip the weld on -AN, now you have a time consuming repair

Last edited by THE 383 admiral; 02-10-2012 at 10:43 PM.

#10

Melting Slicks

I need to do that to my fuel rails can you send me some more info? Like what size are the an fittings you used? Did you have a shop do the drill and tap? One of my rails has a crimped line in it how is the best way to remove it? Do I just use a dremmel grinder and remove the crimp?

#11

Pro

This brings back memories. My rails are drilled and tapped. Fed by dual fuel lines and pumps. Feeds 598 rwhp. This engines twin with the addition of nitrous puts out 786+ rwhp. It's necessary

#12

Racer

I need to do that to my fuel rails can you send me some more info? Like what size are the an fittings you used? Did you have a shop do the drill and tap? One of my rails has a crimped line in it how is the best way to remove it? Do I just use a dremmel grinder and remove the crimp?

#13

To start the threads. I put my tap in my drill press. I also have a duel micro adjust table with a vise clamped in.. I dialed the table to center the fuel rail. then completed by hand.. you can use a 45 deg or 60 deg counter sink for the tapered ends.. just keep checking with the oring on the fitting till the correct depth is reached... The oring size is 1/8 inch and just needs to be snug on the shoulder of the 3/4 -an fitting 6 or 8 -an for your fuel lines your preference

And yes.. drill out the factory crimp on the oe rail

And yes.. drill out the factory crimp on the oe rail

Last edited by THE 383 admiral; 03-09-2012 at 01:32 PM.

#14

Safety Car

I think you can just look for an experienced welder or shoppe its relatively simple. mine were done like 8 years ago and i forget what size AN fittings we used. needed to the room to put a small cap dizzy back there .

#15

that costs money if you do not have a tig. If the fitting gets damaged

You need to cut & clean and pay again for a re-weld

It's a 3/4 in tap tread it... It's aluminum very easy

You need to cut & clean and pay again for a re-weld

It's a 3/4 in tap tread it... It's aluminum very easy